DECONSTRUCTION OF ARTIFICIAL TURF SYSTEMS

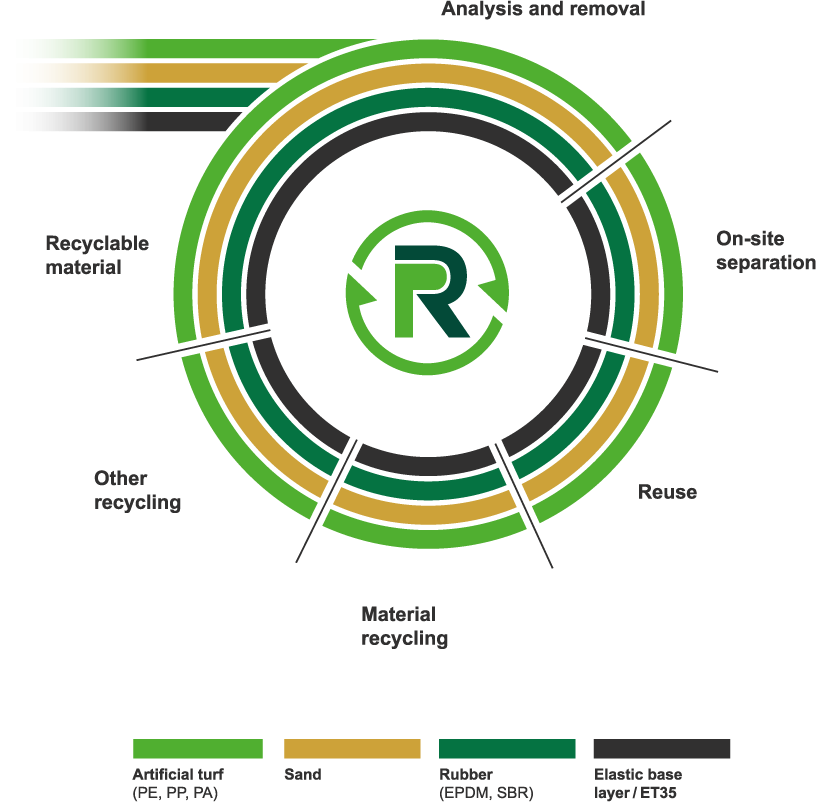

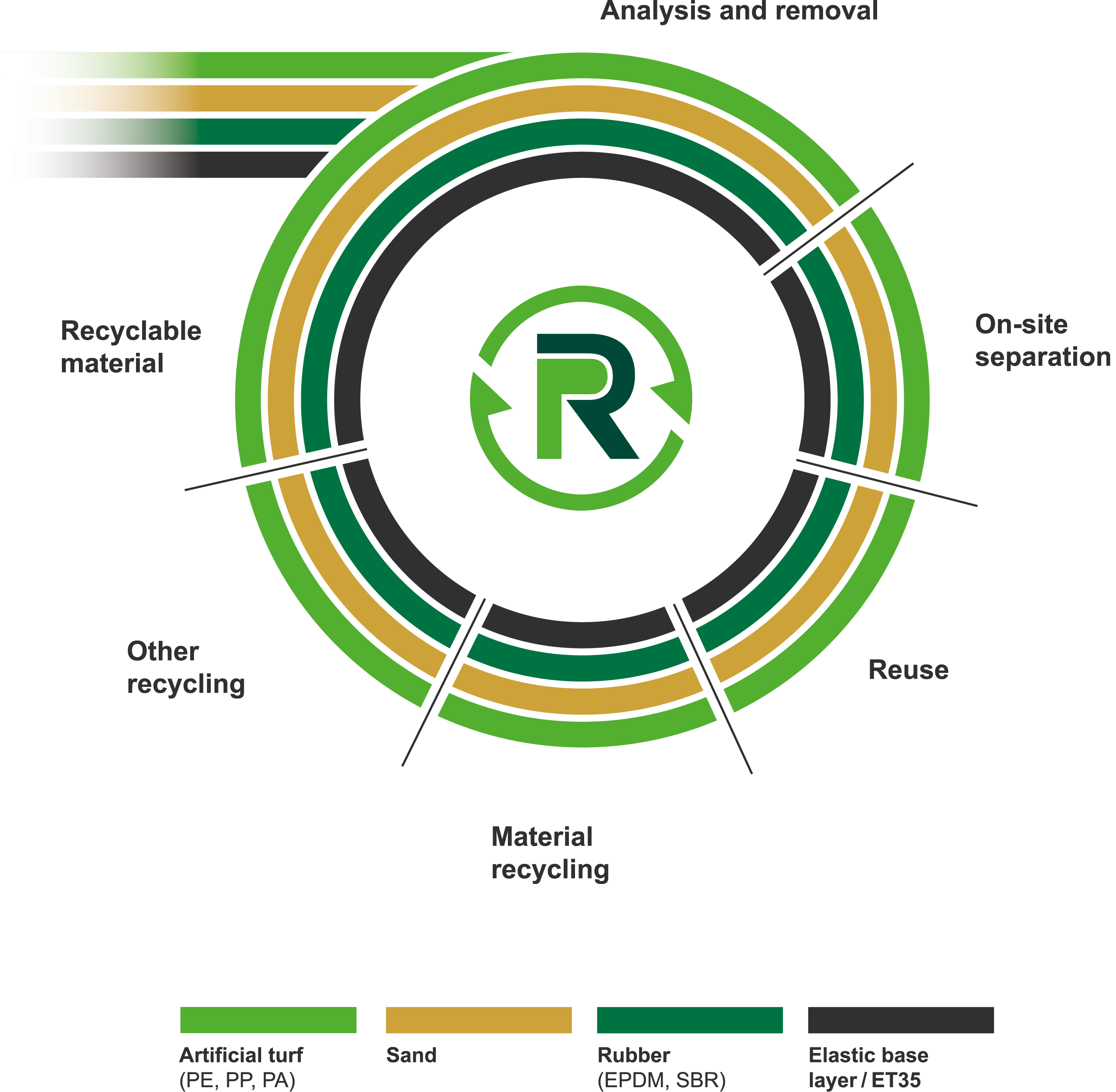

For the removal and separation of an artificial turf system, the mass of the components is of particular importance. While the artificial turf itself usually accounts for less than 10% of the mass, the sand in a 40 mm artificial turf system, for example, dominates with more than 70% of the mass.

As a result, more than 35,000 tons of waste materials from deconstructed artificial turf systems are produced each year in Germany alone. However, only a small percentage of this comes from the artificial turf itself. The separation of the individual components is therefore all the more important for reuse and recycling.

As a result, more than 35,000 tons of waste materials from deconstructed artificial turf systems are produced each year in Germany alone. However, only a small percentage of this comes from the artificial turf itself. The separation of the individual components is therefore all the more important for reuse and recycling.

REMOVAL AND INSITU SEPARATION OF ARTIFICIAL TURF SYSTEMS

– separation of infill (rubber), sand and artificial turf

– or

– separation of artificial turf and sand-rubber mixture

– separation of infill (rubber), sand and artificial turf

– or

– separation of artificial turf and sand-rubber mixture

ALTERNATIVE: REMOVAL OF THE COMPLETE ARTIFICIAL TURF SYSTEM

Der Vorteil liegt im schnelleren Ausbau. Anschließend muss das gesamte Rasensystem jedoch zu einer Verwertungsstelle gefahren werden, in der die einzelnen Komponenten erst voneinander getrennt und verwertet werden können.

The advantage lies in the faster removal. However, the entire turf system must then be transported to a recycling center where the individual components can first be separated and recycled.

REMOVAL AND RECYCLING OF SAND AND INFILL

DECONSTRUCTION ELASTIC LAYERS

If EL or ET are to be renewed, the same quantity of material is usually re-procured and transported to the construction site. This results in more than 20 semitrailer truck trips for the outward and return journeys.

If EL or ET are to be renewed, the same quantity of material is usually re-procured and transported to the construction site. This results in more than 20 semitrailer truck trips for the outward and return journeys.

RESET PROCESS

HOW WE WORK

With our experience, we can draw on a comprehensive knowledge of installed artificial turf systems over the past 30 years. A detailed description of the artificial turf system to be recycled in the tender nevertheless makes it easier for us to prepare an environmentally sound and professional offer. This includes descriptions of the type of artificial turf components and, if applicable, their composition and their masses, such as sand and infill.

A calculation can be made at a flat rate, per square meter or by the ton. It always makes sense to specify the corresponding waste code (AVV) per component. If material analyses are available, they should ideally be attached to the tender.

Mit unserer Erfahrung greifen wir dabei zurück, auf ein umfassendes Wissen, was verbaute Kunstrasensysteme der letzten 30 Jahre betrifft. Eine detaillierte Beschreibung des zu verwertenden Kunstrasensystems in der Ausschreibung, erleichtert es uns dennoch, ein umwelt- und fachgerechtes Angebot zu erstellen. Dazu gehören Beschreibungen über die Art der Kunstrasen-Komponenten und gegebenenfalls deren Zusammensetzung und ihre Massen, wie Sand und Infill.

Eine Berechnung kann pauschal, pro Quadratmeter oder nach Tonnen erfolgen. Eine Angabe der entsprechenden Abfallschlüssel (AVV) pro Komponente ist dabei immer sinnvoll. Sollten Materialanalysen vorliegen, sind diese idealerweise der Ausschreibung beizufügen.

Als Auftraggebende können Sie zudem Angaben zur gewünschten Qualifikation des Ausbau- und Verwertungsunternehmens machen. Nachweisen lassen können Sie sich diese durch Zulassungen oder Zertifikate, wie z. B. Präqualifikation BAU, zertifizierter Entsorgungsfachbetrieb (EfB) EU-Lizenz für Speditionen oder dem Qualitätsmanagement nach DIN ISO 9001.