WHAT DO WE DO? –

EXPERTS IN THE RECYCLING OF ARTIFICIAL TURF AND TARTAN

As one of the pioneers in the recycling of sports surfaces, our world has revolved around the removal, recycling and recovery of artificial turf and tartan surfaces for more than 30 years. With Swabian inventiveness and sustainable thinking, we combine experience and innovation under one roof. For our customers, we offer holistic solutions as a service provider in the construction industry, as a specialist recycling & waste management company and as a specialist freight forwarder.

WHAT DO WE DO? – EXPERTS IN THE RECYCLING OF ARTIFICIAL TURF AND TARTAN

Innovation

Our innovation: The RESET process!

PR Recycling is the first company worldwide to have a mobile recycling plant that makes it possible to recycle elastic layers and elastic base layers on site and make them immediately available for reuse.

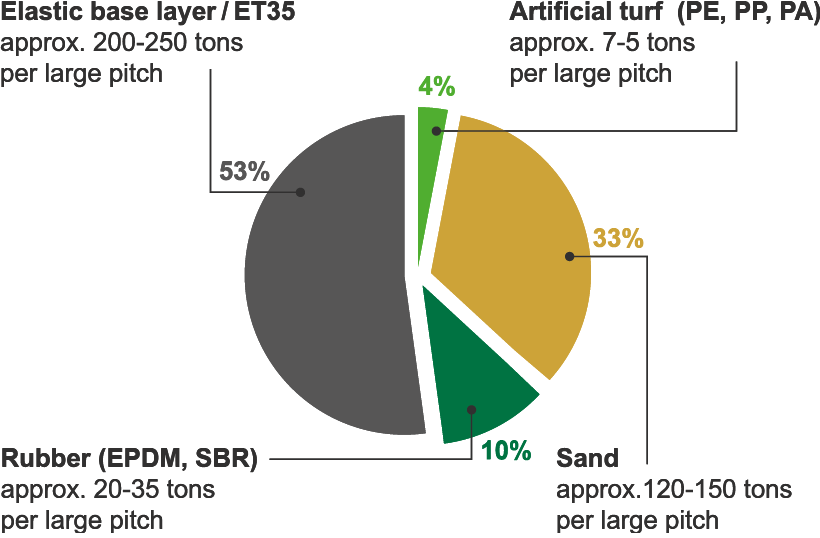

This step alone already recycles 50% of all materials used for an artificial turf pitch in a resource-saving manner and reuses them for the same purpose on site. This eliminates the need for around 20 truck journeys of up to 10,000 km that would normally be required to remove old materials and deliver new ones.

With the reset process, we recycle on site. This sustainably lowers the impact on the environment, for example by reducing CO₂ emissions, and reduces the costs incurred for our customers.

Sustainability

History

Introduction and certification according to DIN ISO 9001.

In cooperation with partners, PR Recycling will offer the services of the first plant in Germany that enables high-quality and clean separation of the sand-rubber mixture used in sports surfaces.

PR Recycling celebrates its 30th anniversary

-

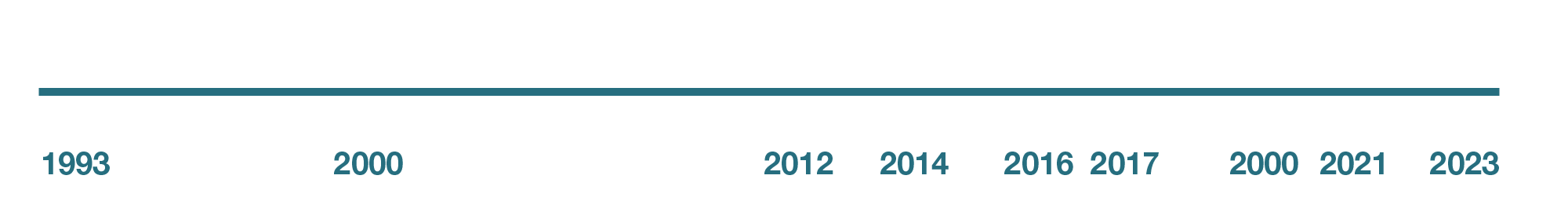

1993Hannelore Pfeiffer-Raff and Helmut Raff found PR Recycling in Filderstadt. As one of the first companies worldwide, they focus on the deconstruction of sports facilities.

-

2000PR Recycling continues to develop and from then on combines recycling, sports facility construction and forwarding under one roof.

-

2012Philipp Raff joins the company as "junior" boss.

-

2014As one of the first companies worldwide, PR Recycling puts the first SMG TurfMuncher into operation.

-

2016The company qualifies as a certified waste management company and has been audited annually since then.

-

2017PR Recycling changes its name to PR Recycling GmbH.

-

2020A new generation takes over the management of PR Recycling - and brings its own ideas and innovations into the company. However, the basic idea of sustainable recycling of sports surfaces remains. The company is certified as a prequalified construction company.

-

2021Introduction of INSITU recycling of elastic (base) layers. Saved disposal for the environment: 200 to 250 t of rubber granulate per sports field.

Introduction and certification according to DIN ISO 9001.

In cooperation with partners, PR Recycling will offer the services of the first plant in Germany that enables high-quality and clean separation of the sand-rubber mixture used in sports surfaces.

-

2023

PR Recycling celebrates its 30th anniversary

We are awarded

In addition, we are involved in recycling working groups of the RAL associations and the European ESTC association. We also present our solutions at sports associations and the IAKS.

Darüber hinaus engagieren wir uns in Recycling-Arbeitsgruppen der Verbände RAL und des europäischen Verbandes ESTC. Unsere Lösungen präsentieren wir zudem bei Sportverbänden und der IAKS.

Downloads

If you are interested, please contact us for access to our download area.

Bei Interesse kontaktieren Sie uns bitte für den Zugang zu unserem Downloadbereich.